Water/Wastewater

Aftermarket Services for Ultrafiltration, Membrane Bioreactor, Reverse Osmosis and Electrodialysis Reversal Installations Expanded

Oct 11 2012

After recently attending the WEFTEC exhibition in New Orleans, GE (USA) have announced that their new technologically advanced remote monitoring and diagnostics (RMD) services are available to all their customers using GE's ultrafiltration (UF), membrane bioreactor (MBR), reverse osmosis (RO) and electrodialysis reversal (EDR) products.

GE's lifecycle services offer their customers a remote monitoring and diagnostic service including both off and on-site technical support as well as a 24/7 technical support help line, smart parts packages as well as conversions, modifications and upgrades.

The RMD service that GE offer will integrate agile software, data and analytics with GE process experts to assist customers in making better and more timely decisions about plant and process operations.

This RMD software helps to detect and therefore prevent problems by measuring critical process variables. The RMD software will collect data from water systems and present this data in graphs that are easy-to-read. Plant data can also be stored and recovered to distinguish trends and assist the operators with any potential issues. This helps to run facilities more efficiently, avoid operational interruptions and most importantly, reduce operational costs.

Customers have the option of choosing a monitor package with their RMD software that provides them with a GE process expert assigned to their site. The process expert will monitor the customer’s site frequently using the new RMD software and will provide the customer with biweekly process reports to highlight plant performance and opportunities for optimisation.

“Our customers now have access to the latest evolution in remote monitoring and diagnostics. It allows operators to keep an eye on their plants around the clock, from anywhere in the world. This helps them move from being reactive to proactive, increasing production and efficiency while reducing costs,” said Yuvbir Singh, general manager—water and process technologies for GE Power & Water.

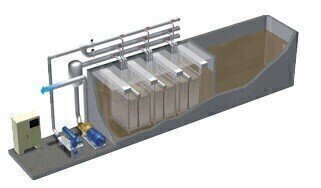

GE’s lifecycle services newly expanded offerings also include the option to upgrade existing MBR systems to LEAPmbr including hardware, installation assistance and an engineering review. Upgrading an existing MBR system to LEAPmbr allows customers to increase productivity, get more capacity in their existing footprint, simplify their design by reducing membrane aeration equipment and eliminating air cyclic valves and decrease their energy usage.

Events

Carrefour des Gestions Locales de L'eau

Jan 22 2025 Rennes, France

Jan 29 2025 Tokyo, Japan

Feb 05 2025 Nantes, France

Feb 16 2025 Kampala, Uganda

Feb 26 2025 Chennai, India

-as-feedstock.jpg)