Water/Wastewater

Advanced Ultrafiltration Membrane to Reduce Carbon Emissions by Over 30%

Feb 27 2025

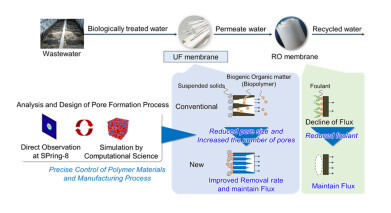

Toray Industries, has unveiled an innovative high-efficiency ultrafiltration (UF) membrane that reduces carbon dioxide emissions by more than 30%. This new membrane maintains high water permeability, while easing the burden on reverse osmosis (RO) membranes, ensuring stable long-term production of high-quality water in wastewater reuse applications.

As global water demand continues to rise, the use of hybrid UF and RO membranes for recycling wastewater and industrial effluent is rapidly growing. Efforts are intensifying to reuse water for drinking and to produce ultrapure water, which is critical for semiconductor manufacturing. Traditional UF membranes, however, struggle to remove biopolymers commonly present in wastewater, leading to more frequent cleaning of RO membranes with chemicals, driving up both water production costs and carbon emissions.

Toray has addressed this challenge by analysing the formation of sub-10-nanometer nanopores and leveraging advanced technology, including the SPring-8 large synchrotron radiation facility. By simulating and closely examining membrane structure, Toray optimised the polymer materials and manufacturing process. This precision allowed the company to create finer pores and a higher density of nanopores, resulting in a UF membrane that achieves unprecedented performance in biopolymer removal while maintaining high water permeability.

Testing confirmed that the new membrane significantly reduces biopolymer transmission—one of the primary contributors to RO membrane contamination—by over two-thirds compared to Toray's current offerings. This breakthrough ensures excellent removal capabilities for both sewage and industrial wastewater. Pilot operations at a sewage treatment plant demonstrated that linking the new UF membrane with RO membranes maintained high water permeability and reduced the decline in RO membrane performance by one-third.

This technology promises to reduce the frequency of RO membrane cleaning in wastewater reuse, especially in sewage treatment and industrial wastewater recycling across sectors such as chemicals, steel, and textiles. It will also help minimise the use of chemicals for cleaning, reduce operational issues, and extend the lifespan of RO membranes. As a result, it lowers water treatment costs and reduces carbon dioxide emissions from the replacement and disposal of RO membranes by over 30%.

Toray plans to begin mass production of the new UF membrane in mid-2025, initially launching it in North America, where wastewater reuse is rapidly expanding, followed by distribution in Japan and other regions. The company will showcase the underlying technology at the Membrane Technology Conference, one of the world’s largest events of its kind, in the United States on February 24.

This development aligns with Toray’s commitment to innovation that fosters a sustainable economy, reflecting its corporate philosophy of contributing to society through new value creation powered by innovative ideas, technologies, and products.

Events

Jul 23 2025 Sydney, Australia

Aug 24 2025 Stockholm, Sweden and online

Aug 27 2025 Busan, South Korea

Sep 02 2025 Mexico City, Mexico

Sep 02 2025 Mexico City, Mexico