Water/Wastewater

Metcalfe Farms boosts slurry transfer system with Landia pumps

Jan 24 2025

At its dairy operation in the Yorkshire Dales, Metcalfe Farms has taken a major step towards future-proofing its slurry management with the addition of new separators, allowing for the efficient transfer of slurry from its 2,000 cows (1,300 dairy cows).

While separating slurry offers clear advantages, designing an efficient slurry transfer system to serve three tanks has proven challenging—particularly with the added requirement of feeding the site’s 200kWh biogas plant.

One of the initial hurdles was improving the final pump in the system, which transfers slurry (containing 6% to 8% dry matter) about 120 meters and up 10 meters to the 3,500m3 anaerobic digester. The pump frequently became clogged due to debris that inevitably finds its way into the slurry.

“I dreaded coming down here to sort it out,” said Robert Metcalfe, who handles engineering for the dairy. “The pump worked fine when it was running, but it struggled with solids. It wasn’t a fun job, spending over an hour unblocking it each time. It was a two-man job, so very time-consuming, especially when you had to retrieve it with a pipe because there was no clutch at the bottom.”

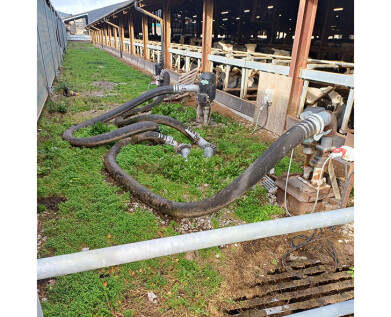

That all changed with the installation of a Landia Chopper Pump, replacing the old unit. Landia also supplied an integrated guide rail and a bespoke pipework system, which has made maintenance much easier.

“It’s a much better design,” Robert explained. “Everything flows much more smoothly now. You don’t have to worry about pipe bending or the extra weight from the added pipe. The new pump rarely blocks. Just recently, a chunk of rope caused an issue, but it was a one-person job to fix, and only took 20 minutes.”

Digestate powers sustainability at Metcalfe Farms

Metcalfe Farms’ biogas plant, managed by Iona Management Services, has recently added a second CHP engine to increase its clean energy output to the grid. The farm provides slurry as a feedstock to the anaerobic digester and purchases energy at a discounted rate for its operations. In winter, the farm uses around 300 kilowatt hours, rising to 360 kilowatt hours in summer.

The digestate from the plant also plays a crucial role in the farm’s sustainability. “The digestate is great for our grassland,” Robert shared. “We spread some on crops, but mainly on the grass. This year, we did five cuts over 1,000 acres. We don’t spend much on chemical fertilisers anymore.”

Working with Landia to integrate the new separators, Metcalfe Farms chose a 22kW pump to manage the slurry feeding task, while an older Landia pump, moved from another tank, continues to work after over 20 years of service.

“We’ve had this pump since 2004,” said Robert. “It’s obviously worn over time, but when Landia engineers tested it, it was still pumping full pipe—something I didn’t expect. Now, with the separators, we can remove solids, which reduces our environmental impact.”

A new 7.5kW Landia Chopper Pump replaced an older long-shaft unit, ensuring that slurry levels remain stable. The original Landia long-shaft chopper pumps, which have been in use for over 20 years, continue to serve the farm.

Reliability and efficiency with Landia Pumps

“The pumps are very well built,” Robert noted. “What I like about them is that they’re electric and modular, so we don’t have to rely on a tractor. This is in line with our goal of reducing engine use and diesel consumption. We’ve had one Landia pump for three years, and it’s never caused any trouble.”

In the milking parlour, Robert is pleased to have moved on from small vortex pumps that frequently failed due to foreign debris. “Whenever plastics or other debris got in, the pumps would burn out or fail. We were replacing them every six months. I called Landia for help,” he said. “The new 5.5kW Landia pump has been fantastic. It handles debris and solids without issue and is completely automatic. Since installation, we haven’t had to touch it. The pump knows when to keep the tank emptied and works seamlessly.”

Integrating pump systems with separators is part of Metcalfe Farms’ broader strategy to improve efficiency while keeping expansion manageable. The farm produces around 45 tonnes of milk per day, which is supplied to Paynes Dairies at Boroughbridge. High animal welfare standards continue to drive increased milk yields.

“Every detail matters as we move forward,” Robert reflected. “We’re considering sand bedding, though our slurry channels might not handle it, and the wear on pumps is a concern. The sawdust we use works well, although it’s expensive.”

Improvements have also been made to cow comfort, with a new dimmable lighting system and roof sheets that block out heat. “During hot spells, the cows were uncomfortable, which affected milk output,” Robert explained. “The new system has made a big difference.”

Looking ahead, Robert plans to phase out other pump brands as they reach the end of their service life, sticking with Landia. “They specialise in pumps, not everything under the sun, and we always get excellent backup and parts support,” he concluded.

Events

Apr 30 2025 Ankara, Turkey

May 11 2025 Vienna, Austria

May 18 2025 Algiers, Algeria

23rd International Water Management Exhibition

May 20 2025 Prague, Czech Republic

Singapore International Water Week Spotlight 2025

Jun 23 2025 Singapore

-with-Josh-Edge-from-Landia-.jpg)

-and-Landia's-Josh-Edge..jpg)

-with-Josh-Edge-from-Landia-.jpg)

-and-Landia's-Josh-Edge..jpg)