Water/Wastewater

Shipping Companies Should Rely on More than Just a “Beta” Ballast Water Treatment Technology

Oct 14 2015

Equipment must help a vessel’s ability to trade, not hurt it. Knowingly subjecting customers to each

iteration of product development is not innovation, it is experimentation that wastes vessel owner’s time

and money. Innovation is the relentless drive to provide solutions that not only help to facilitate trade, but

also ensure full and reliable compliance. In ballast water treatment, it begins with a fundamental

understanding of what is needed from the perspective of a customer.

“It’s our responsibility to provide shipping companies with technology that will enable them to trade and

conduct business as easy and efficiently as possible,” says Dipl.-Ing. Sven Jadzinski, responsible for

sales support in the Product Line Marine & Energy. “With an extremely compact system boasting a

proven UV solo lamp technology, and the lowest electrical power draw in its class, the GEA

BallastMaster marineX, powered by Trojan Marinex is outstanding to none.”

Trojan Marinex and GEA

Trojan Marinex is a Trojan Technologies business. Trojan Technologies is the largest UV water

treatment company in the world, treating a collective flow rate of over 8 million m3/h. Trojan is renowned

for expertise in creating, customizing and optimizing UV technology under the highest risk conditions

where human well-being literally depends on the equipment operating exactly as needed. Take New

York City, for example. In order to meet stringent drinking water regulations, Trojan provided a UV

treatment system that plays a critical role in supplying safe drinking water to nearly 9 million people. This

system treats a flow rate of 395,000 m3/h – that is equivalent to 66 VLCCs.

Direct access to nearly 40 years of industry-defining water treatment expertise, in combination with

steadfast backing, has enabled Trojan to create a suite of ballast water treatment systems unlike any

other. These systems are purpose-built for the marine environment, and provide filtration + UV in a

single, compact unit. GEA and Trojan have partnered to market and sell these systems under the

product name GEA BallastMaster marineX, powered by Trojan Marinex.

“Trojan exists to serve customers, and our strategic partnership with GEA accomplishes this goal,” says

Christian Williamson, Trojan Technologies’ Senior Vice President. “GEA’s reputation and extensive

global service network in the marine industry is one of the best in the world, providing tens of thousands

of vessel operators with 24/7 support and peace of mind. The GEA – Trojan strategic partnership

couples a marine market leader with a water treatment market leader, and the result is shipowners

having confidence knowing that they will receive a solution that will meet their desired needs.”

Interim solutions = unnecessary risks

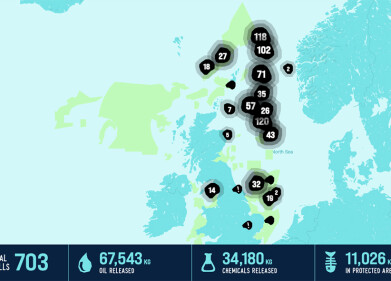

Global compliance is the goal, but with IMO ratification on the horizon and a large group of system

manufacturers still seeking United States Coast Guard (USCG) Type Approval, owners are in an

unenviable position of proceeding with an investment that may not meet their longer-term needs.

Vessels sailing in US waters will be required to adhere with USCG ballast water discharge standards

and the United States Environmental Protection Agency (USEPA) Vessel General Permit (VGP), in

addition to State ballast water regulations. As a temporary measure, the USCG is accepting the use of

Alternate Management System (AMS) that are Typed Approved by other countries on the basis of the

existing Guidelines (G8). However, vessel owners understand that AMS is merely an interim solution and

their vessels will ultimately have to be equipped with a USCG Type Approved system if they’re bound for

ports in the United States.

AMS designation does not provide the manufacturer or the vessel owner any guarantee that the system

will eventually qualify for USCG Type Approval. The specific risk to a vessel owner relying merely on an

AMS system is that the system could need expensive modification or complete replacement should it not

ultimately be Type Approved by the USCG.

Therefore, vessel owners should carefully assess a ballast water treatment supplier’s ability to achieve

USCG Type Approval, question any proclaimed guarantees, and take action with shipyards by providing

minimum specification requirements to ensure longer-term interests are considered, and risks mitigated.

Achieving USCG Type Approval is not an easy task, and can take two to three years of considerable

effort and investment by the supplier, with no guarantee of full certification.

On course for USCG Type Approval

Based on the conviction that USCG Type Approval will become the global standard in ballast water

treatment certifications, Trojan Marinex has executed a comprehensive strategy to be one of the first

suppliers to obtain it.

- Tested in accordance with the USEPA Environmental Technology Verification (ETV) Ballast Water Protocol

Why it matters: The ETV Ballast Water Protocol is a key testing requirement for systems to obtain

USCG Type Approval. Its testing methods are more rigorous, highly prescriptive and consistent,

compared to IMO G8 guidelines.

- Tested at USCG-approved facilities

Why it matters: The USCG requires that Type Approval testing be completed with a certified

Independent Laboratory (IL). This ensures that testing is completed in an accurate and unbiased

manner, to the highest of standards.

- Tested under poor water quality conditions, among the lowest UV transmittances in the industry

Why it matters: Many existing IMO Type Approved systems have been tested in higher clarity

water (high UV transmittance). It is expected that these systems will not be able to treat lower

clarity waters than to what they have been tested to under USCG regulations. The UV

transmission value will be noted on the Type Approval certificate, significantly limiting the

applicability of the system in poorer water qualities.

- Tested under high flow conditions

Why it matters: Many existing IMO Type Approved systems have only been tested at relatively

low flow rates (e.g., < 250 m3/h), and empirical models and simulations were used in an effort to

show performance at higher flow rates. While many systems have been tested at higher flows in

shipboard applications, it is critical that land-based testing be conducted on these systems too.

Parameters can be more closely controlled and land-based tests typically have much higher

organism counts, which effectively simulates worst-case conditions.

- Tested in fresh water, brackish water and marine water

Why it matters: Salinity in ports and harbors around the world vary significantly, therefore it is

necessary to test in all salinities, including fresh water. System suppliers that test in only two

salinities may obtain USCG Type Approval, however, similar to issued AMS certificates, these

systems will only be permitted to operate in water salinities that were tested and approved. If a

system has not been tested in fresh water, it will not be permitted to ballast in fresh water.

In March 2015, a formal application for USCG Type Approval was submitted for the Trojan Marinex BWT

system – this was the first application in the industry.

Global service and support

Based on the conviction that USCG Type Approval will become the global standard in ballast water

treatment certifications, Trojan Marinex has executed a comprehensive strategy to be one of the first

suppliers to obtain it.

Developing a revolutionary ballast water treatment system is one thing; being able to provide global

service and support is another. With dedicated GEA experts in more than 50 sales and service

companies and over 20 authorized workshops throughout the world, vessel owners can focus on their

business knowing that, when needed, an integrated service network is on standby, ready to assist.

For more information about GEA BallastMaster marineX, powered by Trojan Marinex, visit gea.com and

trojanmarinex.com.

Events

Apr 15 2025 Moscow, Russia

Apr 21 2025 Shanghai, China

May 11 2025 Vienna, Austria

May 18 2025 Algiers, Algeria

23rd International Water Management Exhibition

May 20 2025 Prague, Czech Republic