Water/Wastewater

Economical System Design for Dissolved CO2 Removal

Jan 09 2013

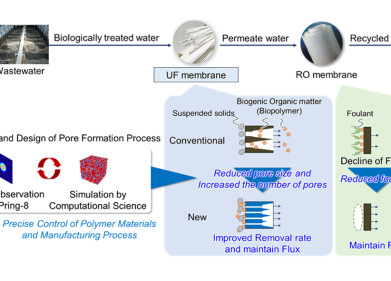

The 8 x 20 Liqui-Cel Membrane Contactor, from Membrana (USA), was designed for customers that need to remove bulk CO2 from industrial water processes where meeting strict regulatory guidelines, such as FDA or NSF, is not required. While the use of less expensive materials and manufacturing process efficiency has allowed Membrana to offer this affordable decarbonation device, significant cost savings can also be realised in the system design.

CO2 removal systems that use Liqui-Cel Extra-Flow Contactors typically require compressed air as a sweep gas and a vacuum pump. However, a system using 8 x 20-inch membrane contactors can be used with a blower in suction mode to pull air through the contactor. This design alternative of using a blower and eliminating the need for compressed air can significantly lower overall system and operating costs. Additionally, piping and other instrumentation (for example, a pressure gauge after the pump) may also be eliminated to further reducing capital and operating costs.

Individual 8 x 20 Liqui-Cel Contactors can process up to 11.4 m3/hr (50 gpm) in one device. Larger flows can be handled by piping multiple contactors in parallel. The product is well-suited for carbon dioxide removal in boiler feed water applications to reduce corrosion, with mixed bed or EDI technologies to reduce chemical use and with many other industrial applications where CO2 can negatively impact processes.

Membrane Contactors are rapidly displacing forced draft de-aerators and vacuum towers in both new and old systems around the world.

Events

Apr 08 2025 Targi Kielce, Poland

Apr 08 2025 Bahrain

Apr 10 2025 Beijing, China

Apr 10 2025 Beijing, China

Apr 15 2025 Moscow, Russia