Water/Wastewater

BIO-CEL® - The Successful Evolution

May 27 2015

Since MICRODYN-NADIR, the membrane and module specialist headquartered in Wiesbaden, Germany, lauchend it’s new product BIO-CEL® BC XL in Mai 2014 the continuous product evolution has reached a new climax – BIO-CEL®BC416.

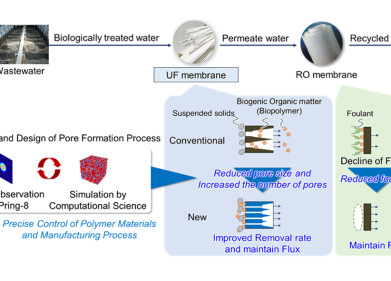

The main application for BIO-CEL® products is a wastewater treatment process called Membrane Bioreactor (MBR), which is a combination of a biological treatment process and a downstream filtration. MBRs show advanatges with regards to demand in space and effluent qaulity compared to standard proceses like convential activited sludge (CAS) systems.

Nowadays, MBRs being operated with submerged membrane modules are state-of-the-art technology. The uniqe construction of the BIO-CEL® comprises the adavantges of both submerged technologies - hollow fibres and flat-sheet modules. Even though the BIO-CEL® looks like a plate & frame system, the construction is based on a two-side polyether sulfone (PES) membrane which is laminated onto a spacer material in order to create a self-supporting sheet. This flat-sheet construction uses the advantages of the plate & frame systems and in addition to that, due to the physically bound laminate over the entire surface of the material, the construction can be backwashed, is flexible and due to the laminate thickness very compact - like a hollow fiber system.

The BIO-CEL® module was initially available as a commercial product in 2005. The market launch of the BIO-CEL® XL took place in 2014 at IFAT Entsorga in Munich, a trade fair for water, sewage, waste and raw materials management.

Today, the BIO-CEL® product line consists of five module types ranging from 10 – 1.920 m2 of membrane area. The latest development is the BIO-CEL® BC416 with 416 m2 of membrane area. Compared to the modules predecessor - the BIO-CEL® BC 400, the BIO-CEL® BC416 is equipped with 4% more membrane are. This increase was possible as the fully automated BIO-CEL® production line was upgraded in order to allow for the automated production of the BIO-CEL® XL modules. The change in the production line allowed an advanced suspension of the membrane sheets mountend within the cassets. This resulted in a equalization of the interspace between the membrane sheet and the frame which is now totally equal between all sheets and from the sheet to the frame. This optimization leads to a more equal air bubble distribution and therfore an optimization of the crossflow. Moreover, it allows for an even higher packing density.

The BIO-CEL® BC400 including all construction parts, such as the 4 cassets and the base frame are a 100% replaceable by the BIO-CEL® BC416 as the dimensions as well as the connections stay the same.

Throught the year, MICRODYN-NADIR will implement these changes with the

BIO-CEL® BC100 as well, which will then be called BIO-CEL® BC104.

ACHEMA 2015 Frankfurt: Please visit us at booth 5.0 E95

AQUATECH 2015 Amsterdam: Please visit us in Hall 3 booth 03.330

Events

Apr 08 2025 Targi Kielce, Poland

Apr 08 2025 Bahrain

Apr 10 2025 Beijing, China

Apr 10 2025 Beijing, China

Apr 15 2025 Moscow, Russia