Water/Wastewater

Working Together to Recycle Industrial Wastewater While Generating Energy

Oct 04 2014

GE (USA) and PurposeEnergy Inc. today announced a collaboration whereby GE’s new anaerobic membrane bioreactor (AnMBR) technology and PurposeEnergy’s Tribrid-Bioreactor will be combined as a solution to reuse industrial wastewater while also turning waste into energy.

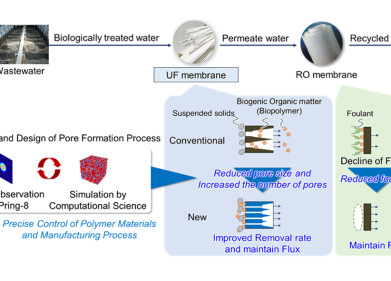

GE’s new AnMBR, which was introduced today at WEFTEC, utilizes its ZeeWeed* 500 membranes in combination with an anaerobic bioprocess. As industrial customers seek lower operating cost and increased efficiency while at the same time facing more stringent discharge limits, AnMBR offers the ability to generate renewable energy and produce superior effluent quality for reclamation and reuse.

PurposeEnergy’s Tribrid-Bioreactor is an anaerobic digester engineered specifically for food and beverage industry byproducts. It converts organic waste into clean water and energy, leading to a reduction in carbon footprint, cost savings and on-site production of renewable energy. Unlike traditional anaerobic digesters, the Tribrid-Bioreactor separates hydraulic retention time from solids retention time. The result is greater than 99 percent reduction in organic load for not only wastewater, but also for solids and slurries that are generated during food and beverage manufacturing.

“We are pleased to be working with GE to bring these innovative technologies to the food and beverage industry. The solutions we are deploying treat organic byproducts, reduce the discharged volume of wastewater by 80 percent and generate renewable heat and power. GE’s AnMBR is helping PurposeEnergy set the new standard for food and beverage byproduct management,” said Eric Fitch, CEO of PurposeEnergy.

Combining PurposeEnergy’s Tribrid-Bioreactor and GE’s AnMBR technology solves the issues associated with traditional anaerobic processes for food and beverage manufacturers. This breakthrough design results in complete retention of biomass and prevents the discharge of both organic and inert solids. The result is a significant improvement in final effluent quality with zero suspended solids.

Anaerobic digestion is a biological process in which microorganisms break down biodegradable material in the absence of oxygen. One of the end products is biogas, which can be combusted to generate electricity and heat. Advantages of anaerobic treatment include energy savings by not requiring oxygen, reduced sludge production and reduced footprint. However, the traditional anaerobic processes have disadvantages such as lesser effluent quality, process sensitivity, slow biomass growth rate, retention of methanogens and difficult-to-settle sludge.

“When AnMBR—GE’s newest membrane technological advancement—is paired with PurposeEnergy’s Tribrid-Bioreactor digester technology, industrial users can reap the benefits of recycling wastewater and generating renewable sources of energy. It is the embodiment of GE’s commitment to energy neutrality,” said Yuvbir Singh, general manager, engineered systems—water and process technologies for GE Power & Water.

Events

Mar 12 2025 Montreal, Canada

Mar 18 2025 Expo Santa Fe, Mexico

Mar 18 2025 Moscow, Russia

Mar 19 2025 Manila, Philippines

Mar 20 2025 Guangzhou, China